Can A Ceramic Cpcitator Be Used If Its Crcke

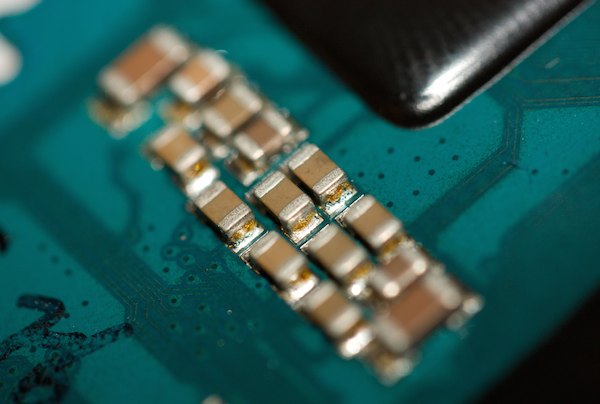

Ceramic disc capacitors are used across brush dc motors to minimize rf noise.

Can a ceramic cpcitator be used if its crcke. In every electronic assembly line where ceramic capacitors are used and printed circuit boards are depaneled the quality risk flex cracks is widely known. Ceramic capacitors can also be used as a general purpose capacitor because of their non polarity and are available in a large variety of capacitances voltage ratings and sizes. Manufacturing can cause cracks to occur in the capacitor element due to expansion and contracting of the board when an mlcc is directly attached to an aluminum circuit board etc having large thermal expansion not to mention at areas near screws or depaneling in addition it is common that boards are bent excessively during board manufacturing or final assembly and fragile ceramic. Ceramic forming techniques include shaping by hand sometimes including a rotation process called throwing slip casting tape casting used for making very thin ceramic capacitors injection molding dry pressing and other variations.

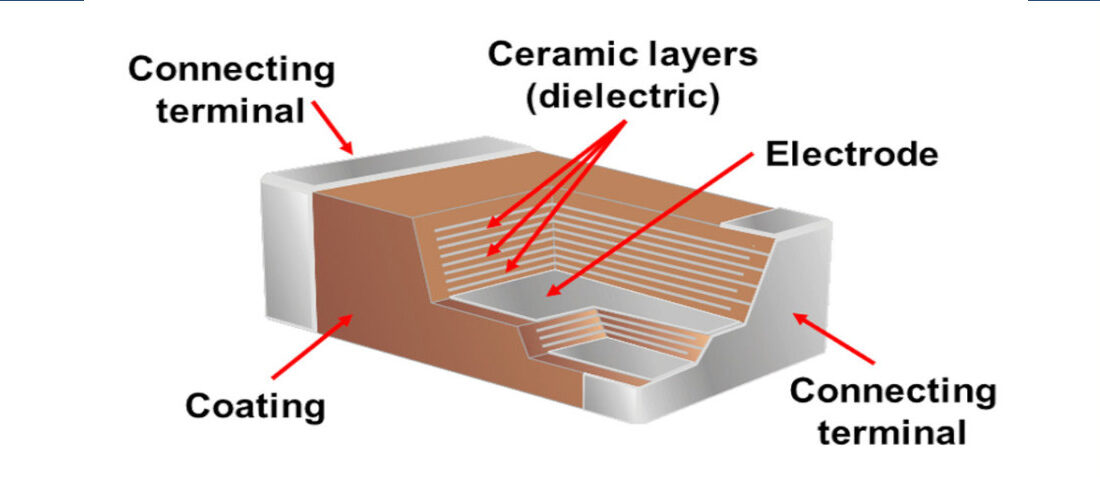

Capacitors store energy in the dielectric not in the conductive. Noncrystalline ceramics being glass tend to be formed from melts. Unfortunately flex cracks in cercaps always extend under the metal terminations of the capacitors and electrical tests only reveal about 1 of the affected parts. Silver that is used in pme capacitors is a metal most susceptible to ecm.

Cracked capacitor stress is a force which produces or tends to produce deformation and is measured as the force applied per unit of area. Ceramic capacitor is made up of ceramic material which acts as a dielectric material for it. The forces applied to the chip exceed its breaking strength the chip will crack. Migration of silver can be observed at voltages as low as 0 4 v and relative humidity down to 40 rh which is the reason of so called low voltage failure phenomena in capacitors.

A ceramic capacitor is a fixed value capacitor where the ceramic material acts as the dielectric it is constructed of two or more alternating layers of ceramic and a metal layer acting as the electrodes the composition of the ceramic material defines the electrical behavior and therefore applications. In a matter of weeks a micro crack can propa gate through the ceramic causing opens intermittents or excessive leakage currents a time bomb due to processing figure 6. Strain is the deformation which results from a stress and is measured as the ratio of the change.