Can I Staple Down 3 4 Engeneer Floor

Group b 3 4 inch engineered on concrete.

Can i staple down 3 4 engeneer floor. He goes step by step through the process of installing the floor and gives y. My biggest concern about most of the guns available are they re only 1 gun. Final costs of installing a nail down floor on plywood over concrete. Use a pneumatic flooring stapler to drive staples through the groove at a 45 degree angle image 1.

Sales rep said this product was either glue down or staple down with 1 4 crown staples. Only certain types of flooring should be installed below grade or on a cement foundation. I just don t see a 1 staple holding that well. I priced it doing glue down it was gonna run about 1 sq ft for glue.

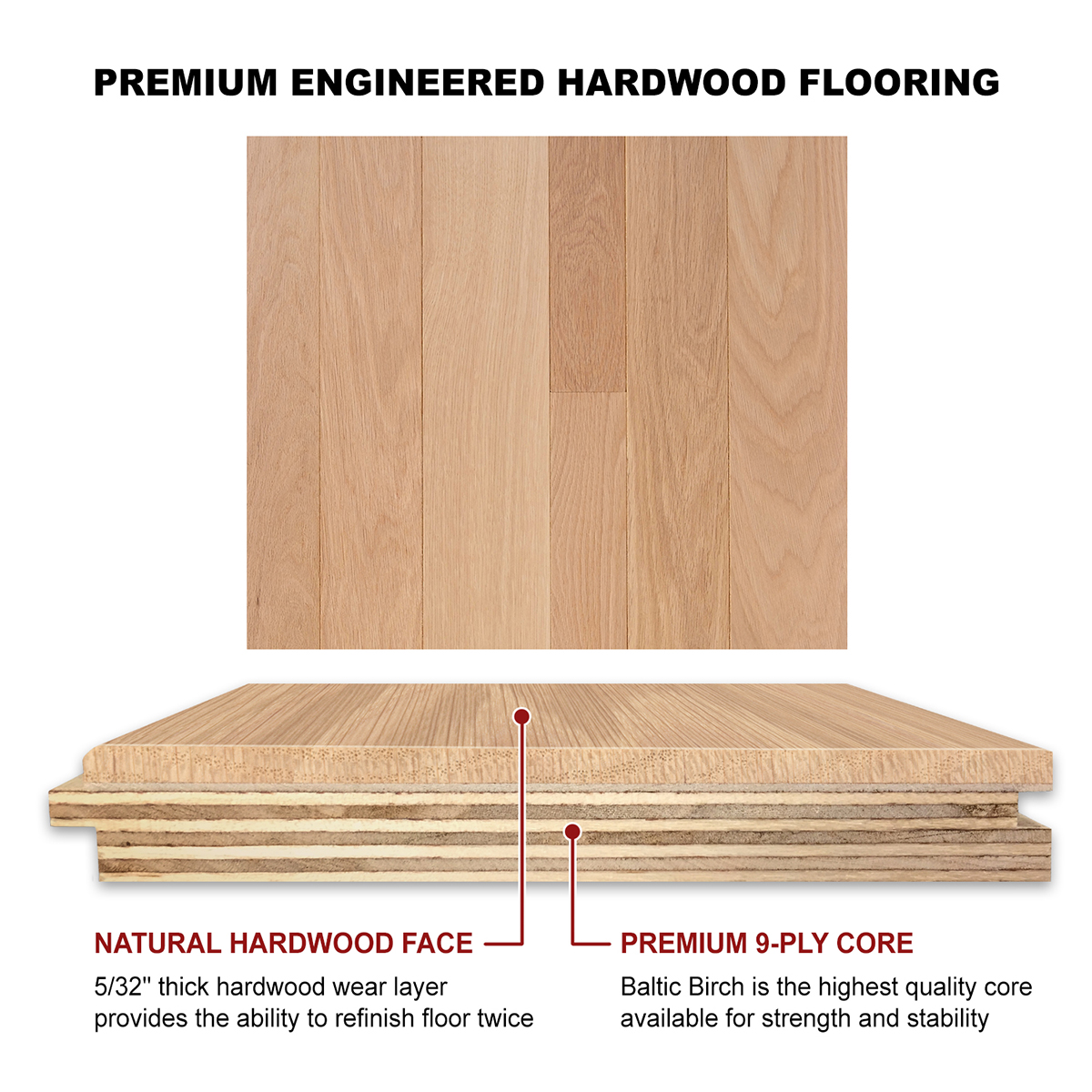

For inch engineered on concrete the first step after proper floor preparation and moisture testing is choosing adhesives and or moisture barriers. 1st is glue vs staples for a 3 8 thick engineered oak plank in 3 width which is going on a 2nd floor plywood subfloor. 3 4 thick engineered planks should be nailed or stapled using a 3 4 solid wood flooring nailer or stapler of any brand. If you choose to fix your hardwood floor into position you then have the choice of either gluing your floor to the subfloor using flexible flooring adhesive to.

When installing a 5 wide product use an 18 gauge 1 1 4 staple or longer with a 1 4 crown. Continue to install the flooring making sure to nail staple 1 2 from the ends and every 3 4 thereafter. Installing a staple down engineered hardwood floor. Engineered hardwood floors can be glued or nailed into position but they also have the option of being floated over an underlay.

700 sq ft will buy 2 guns. Solid hardwood floors must be fixed into position by either gluing or nailing down to the subfloor. The second floor of a home is above grade ground floor is on grade and basement level is below grade. If you are having trouble getting the planks to slide together easily use a rubber mallet to force them together image 2.

In this video jason shows us how to nail down a 3 8 engineered hardwood floor. Nail down most common wood subfloor solid engineered floors only on grade or above grade less risk for sanding. Make certain the tool is adjusted properly to ensure that the fastener is at the proper angle and is flush within the nail pocket. This figure is based on three items.

Moisture barriers come in the form. Use a nail punch and fill the holes with wood filler. For the first row pre drill and nail with finishing nails about 1 inch from the wall at 3 to 4 inch intervals.