Carbon Ceramic Material Properties

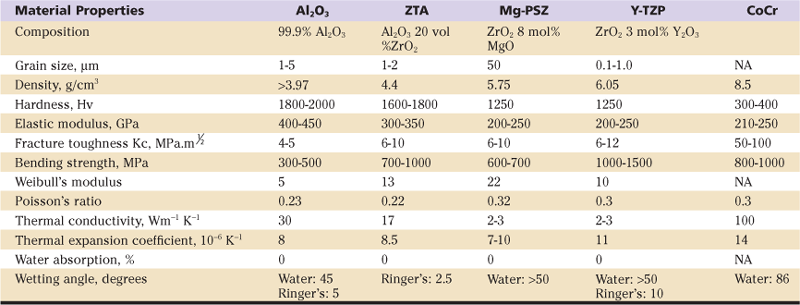

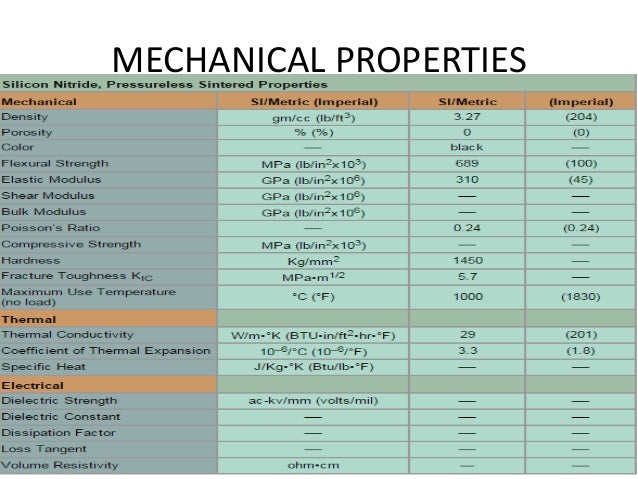

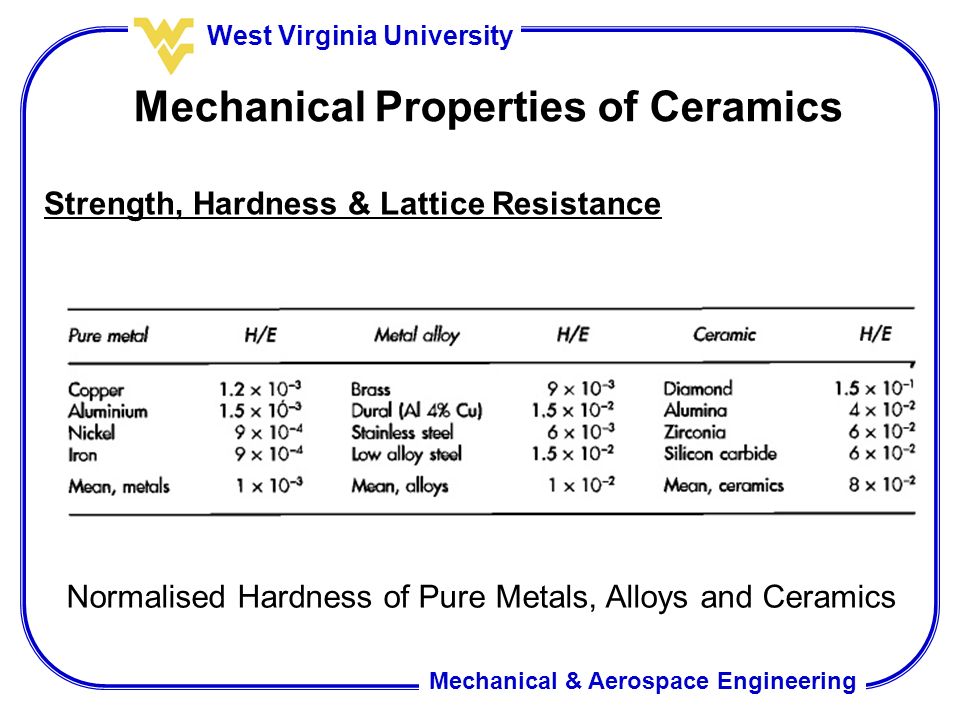

Ceramic composition and properties atomic and molecular nature of ceramic materials and their resulting characteristics and performance in industrial applications.

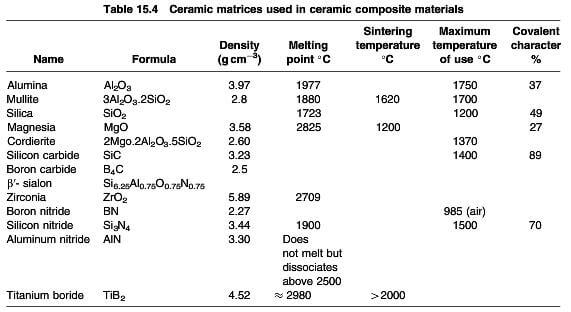

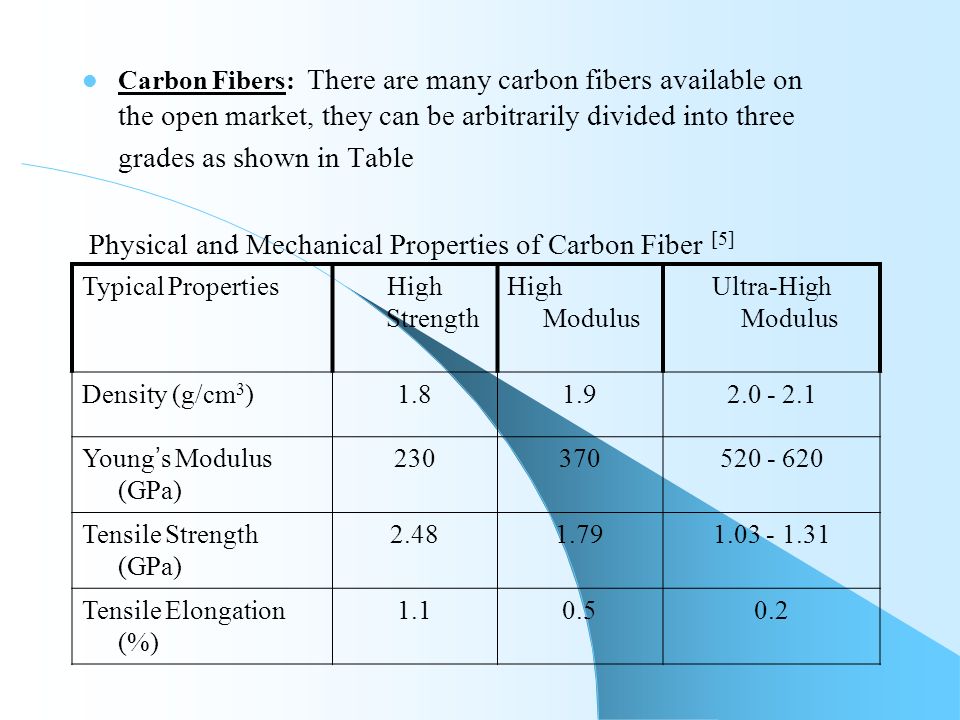

Carbon ceramic material properties. Some are composite materials in which the ceramic forms a kind of background material called the matrix which is reinforced with fibers of another material often carbon fibers or sometimes fibers of a totally different ceramic. While the data in these charts is in most cases typical of what you will find from ceramic component suppliers it is only intended to be a general point of reference and should not be used for material selection or specification. The carbon fibres improve the properties of monolithic carbon by ten times or more with no increase in weight. Ceramic matrix composites cmcs are a subgroup of composite materials as well as a subgroup of ceramics they consist of ceramic fibers embedded in a ceramic matrix.

Not all high tech ceramic materials are simple compounds. Carbon carbon is a non oxide engineering ceramic. Carbon ceramics composites and properties preparation k kobayashi k miyazaki i ogawa t hagio and h yoshida government industria research institute kyushu shuku mach tosu sh saga hen 841 japan abstract fabrication methods for carbon ceramics composites were established by using two different processes of hot pressing and pressureless sintering without any binder phase. A material like this is known as a ceramic matrix.

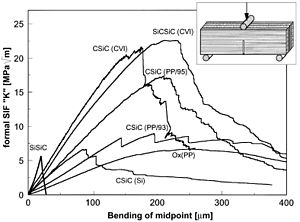

Carbon carbon combines the desirable properties of the two constituent carbon material. Industrial ceramics are commonly understood to be all industrially used materials that are inorganic nonmetallic solids. The deformation at breaking point of c sic materials ranges from 0 1 to 0 3. Carbon fibre reinforced carbon cfrc carbon carbon c c or reinforced carbon carbon rcc is a composite material consisting of carbon fiber reinforcement in a matrix of graphite it was developed for the reentry vehicles of intercontinental ballistic missiles and is most widely known as the material for the nose cone and wing leading edges of the space shuttle orbiter.

Usually they are metal oxides that is compounds of metallic elements and oxygen but many ceramics. A unique feature of carbon carbon composite is that its strength can increase with temperature. We have collected a number of charts detailing applications and properties for some of the most commonly used ceramic materials. The resulting quasiductile properties of the ceramic composite material combine the useful properties of carbon fiber reinforced carbon c c and polychrystalline silicon carbide ceramics.

Carbon carbon is primarily used for extreme high temperatures and friction applications. It has the lowest density among non oxide engineering ceramics. The graph bars on the material properties cards below compare carbon carbon to other non oxide engineering ceramics top and the. Carbon carbon can be tailor made to give a wide variety of products by controlling the choice of fiber type fiber presentation and the matrix.

Figure 16 8 shows the strength properties of several carbon carbon composites and other aerospace materials over a wide temperature.