Ceramic Always Fail In Tension

Industrial ceramics are commonly understood to be all industrially used materials that are inorganic nonmetallic solids.

Ceramic always fail in tension. All five cmcs exhibited a significant dependency of ultimate tensile strength on test rate such that the. Alumina for example has a tensile strength of 20 000 psi 1138 mpa while the compressive strength is 350 000 psi 2400 mpa. Usually they are metal oxides that is compounds of metallic elements and oxygen but many ceramics. They withstand chemical erosion that occurs in other materials subjected to acidic or caustic environments.

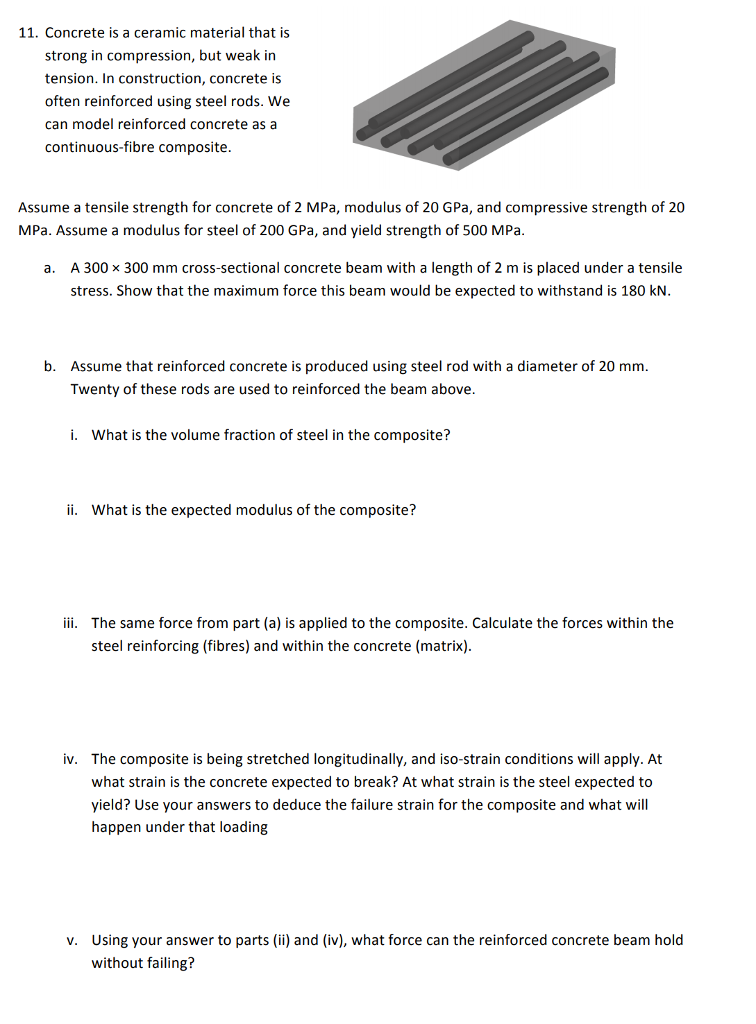

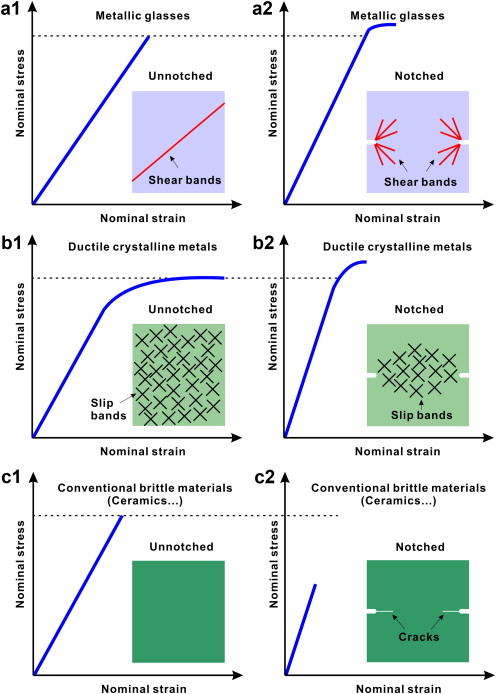

Ultimate tensile strength of five different continuous fiber reinforced ceramic matrix composites cmcs including sic f bsas two dimensional 2d 2 types sic f mas 2d sic f sic 2d and c f sic 2d 2 types was determined as a function of test rate at 1100 1200 c in air. To evaluate the effect of the specimen design on the flexural strength σ f and failure mode of ceramic structures testing the hypothesis that the ceramic material under tension controls the mechanical performance of the structure. A ceramic material is an inorganic non metallic often crystalline oxide nitride or carbide material. Figure1 a the stress amplitude versus cycles to failure curve s n curve inset shows definition of stress amplitude σamp b curves of log dc dn versus log k1.

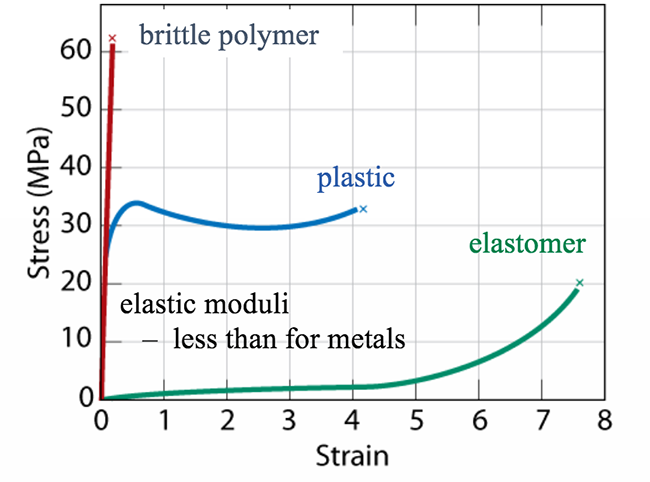

Failure in tension this failure occurs when you stretch a material bit too far. One category of failure with time in glasses and ceramics known as static fatigue is actually stress corrosion cracking promoted by. Why is a rope higher in tensile strength than in compression. Some elements such as carbon or silicon may be considered ceramics ceramic materials are brittle hard strong in compression and weak in shearing and tension.

Before i answer let me ask you a question. Failure for ceramic materials is to examine the energy required to drive cracks through the system. 2 failure types. It is not altogether clear that conventional fatigue actually takes place in ceramic materials.

But let me make a point over here. Mechanical properties of ceramic materials are linked to understanding brittle fracture. In this kind of failure the member is yielded first then the necking phase comes into the picture and then it fails at the reduced cross section. Failure over time does occur in brittle materials however despite the absence ö the crack tip plasticity that is the hallmark of materials known to exhibit fatigue.

Ceramics tend to be weak in tension but strong in compression. Cracks are always perpendicular to the applied stress. Ceramic composition and properties atomic and molecular nature of ceramic materials and their resulting characteristics and performance in industrial applications. When you can reason that out you ll have the key to your answer about ceramics.

The possibilities of this is very rare if the structure is designed properly. Why is a brick wall stronger in com.