Ceramic Ball Mill Definition

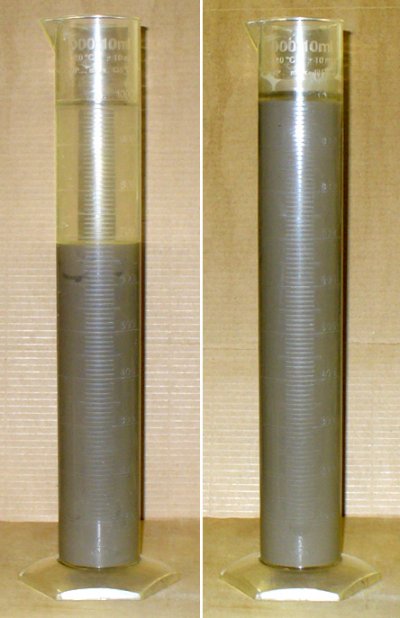

Materials such as clay and glaze components can be broken down in a ball mill by getting placed into rotating or rolling jars with porcelain balls inside them.

Ceramic ball mill definition. A standard cylinder assembly consisting of a new ceramic cylinder and steel hardware with integral shafts can be installed in less than one hour. It works on the principle of impact and attrition. The feed can be dry with less than 3 moisture to minimize ball coating or slurry containing 20 40 water by weight. Ceramic ball mill is the typical grinding equipment which us ball mill ceramics greatly improves the grinding fineness.

Size reduction is done by impact as the balls drop from near the top of the shell. Downtime is kept to a minimum. A grinding mill in which the material to be ground is tumbled in a drum with heavy balls of iron steel or stone. In ceramics ball mills are used to grind down materials into very fine particles.

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes paints pyrotechnics ceramics and selective laser sintering. Porcelain ball mill balls 1 li. Ceramic ball mill with optional explosion proof controls and cooling jacket for temperature control. During milling the porcelain balls pulverized the materials into an incredibly fine powder.

20 20 mm 20 25 mm. The ball mill is a tumbling mill that uses steel balls as the grinding media. Compared with the traditional ball mill such kind of ball mill has a great advantage in function structure and operation.