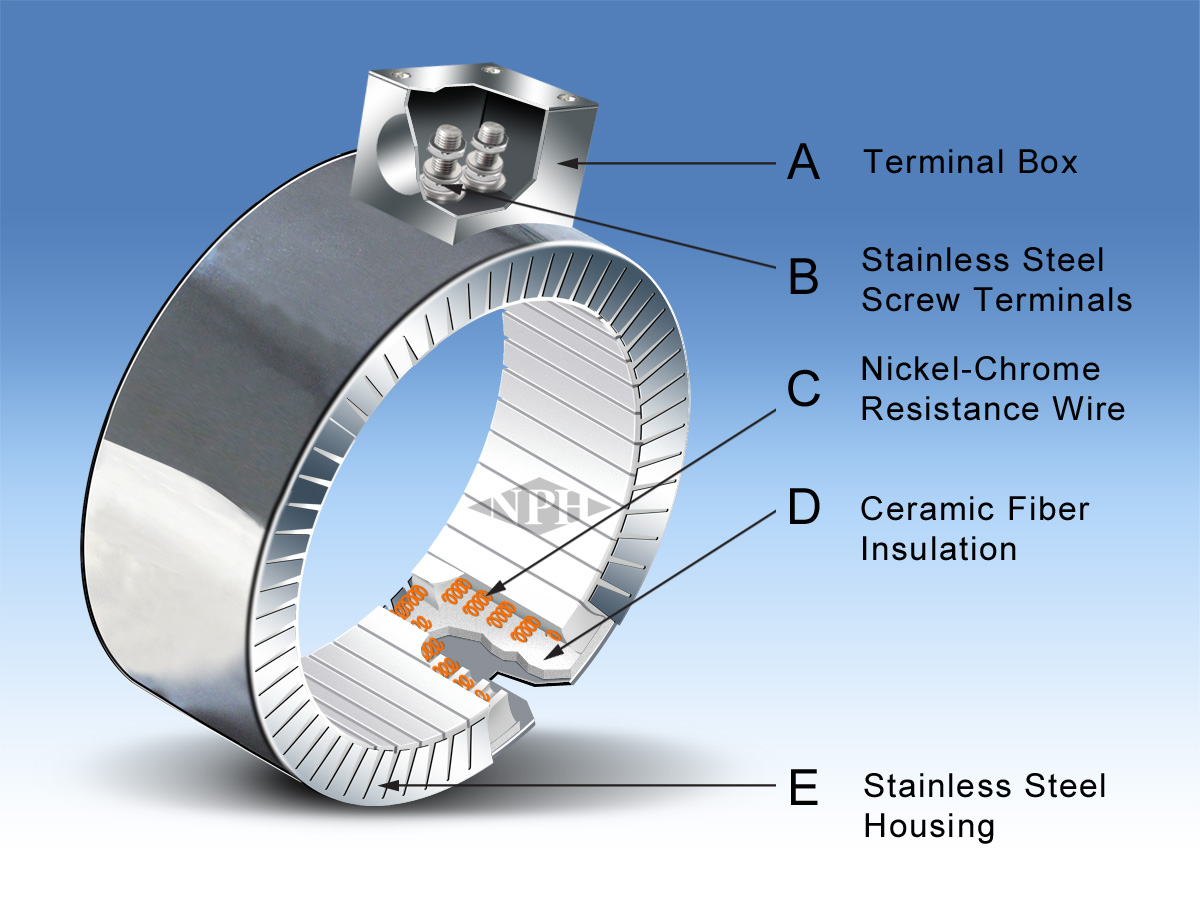

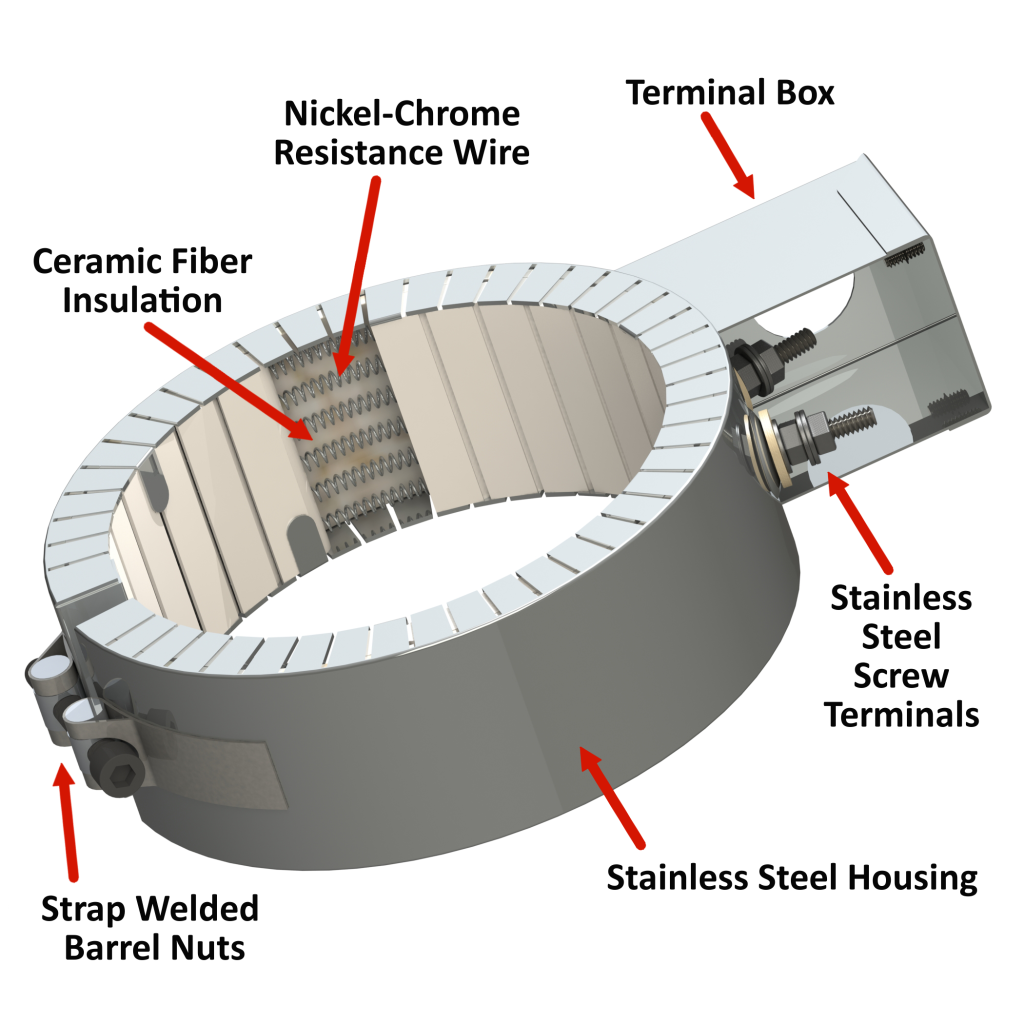

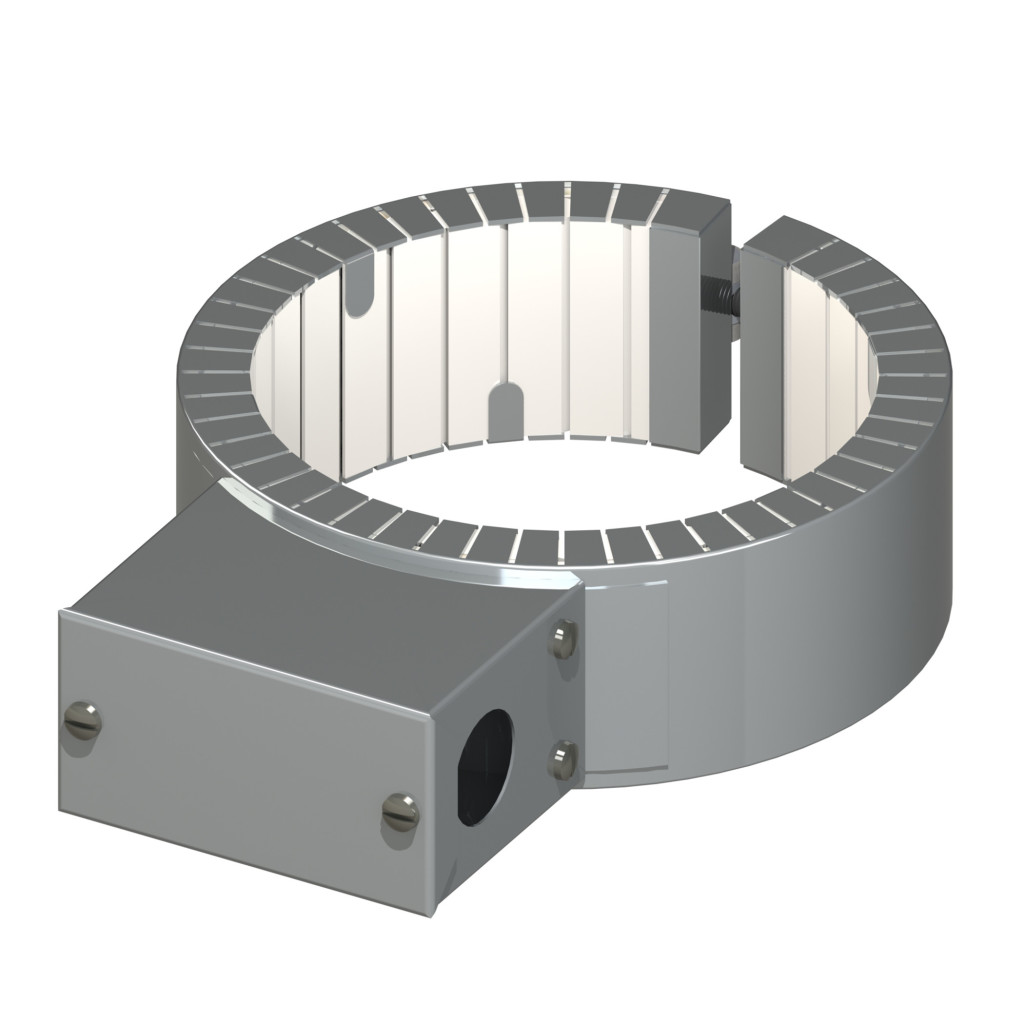

Ceramic Band Heater Construction

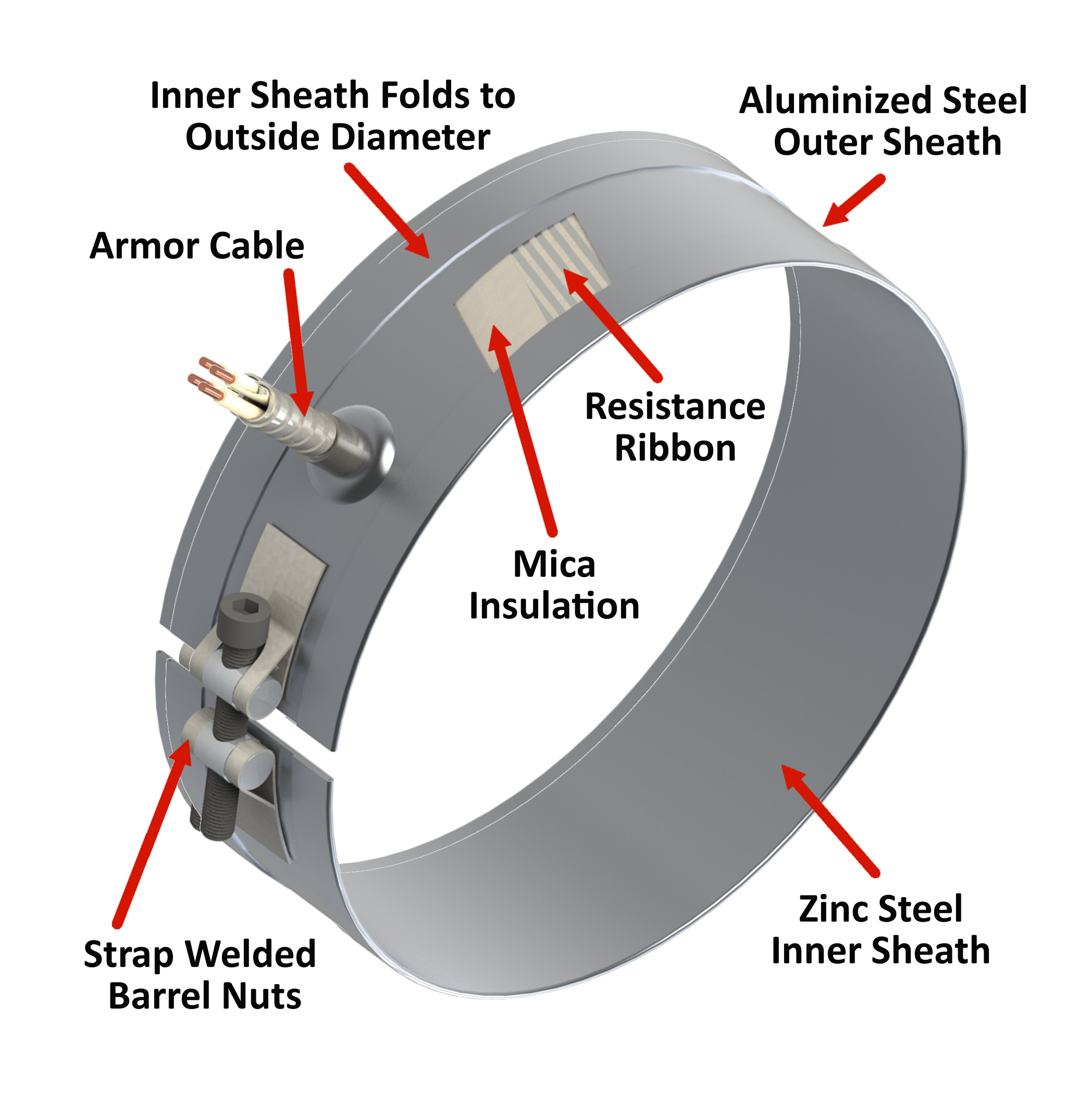

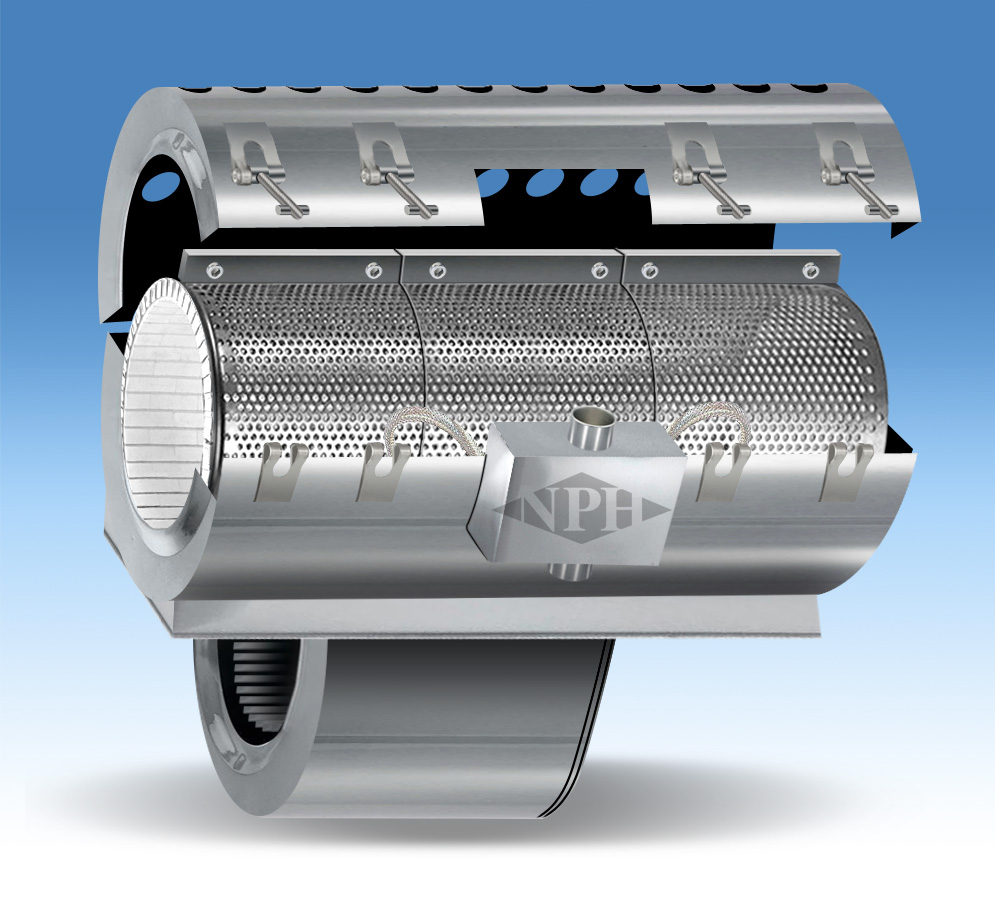

A ceramic fiber insulating mat and a stainless steel jacket cover this assembly.

Ceramic band heater construction. Ceramic band heaters are designed with spirally wound inner resistance coils evenly threaded through interlocking insulated ceramic tiles. This means you can reduce the number of bands used and simplify wiring. The ceramic core or mat of tiles is housed beneath a stainless steel sheet with serrated edges. The preferred choice of oem s omega quality construction.

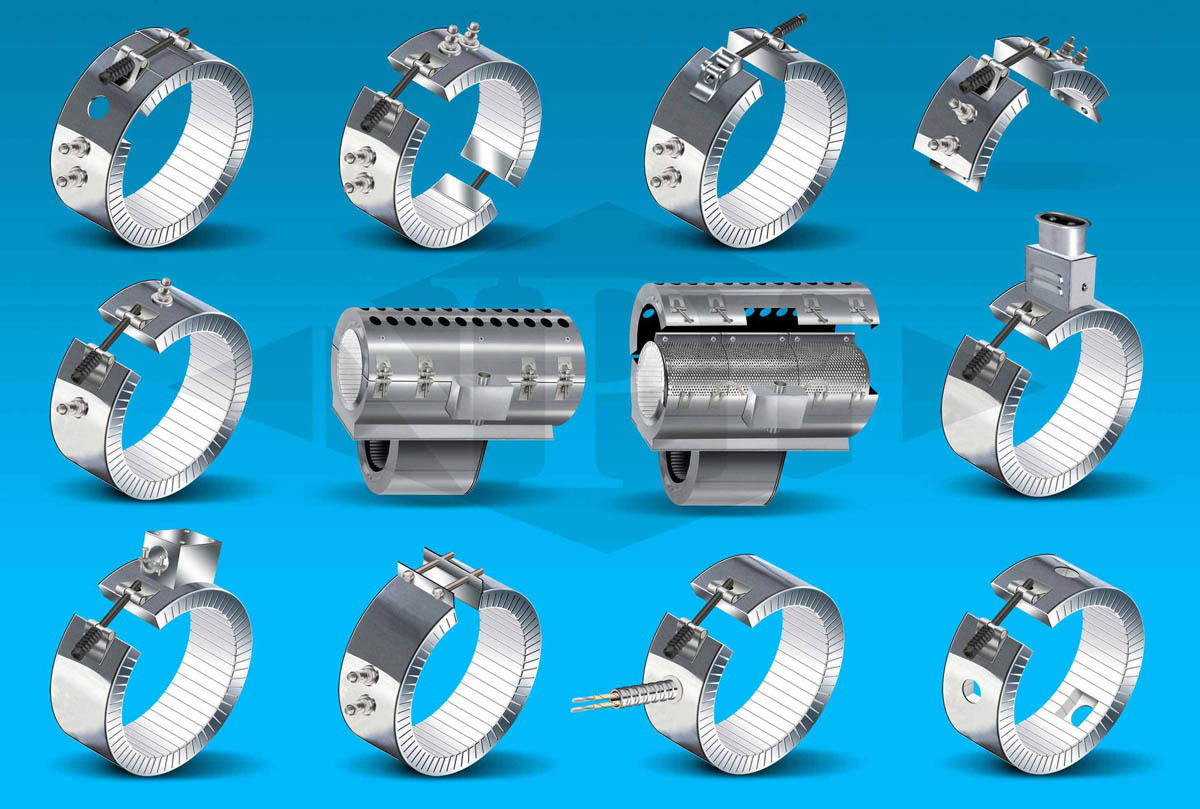

The thin ceramic insulation used results in a lower mass construction which improves response to control and minimizes temperature lag and overshoot. Type r construction is an uninsulated ceramic band heater with a perforated stainless steel outer shell for more efficient cooling. At higher watt densities they can be used in wider increments than other heaters. It is typically used in mulitple quantities with forced air cooling systems such as tempco s cool to the touch shroud systems see type rcc below.

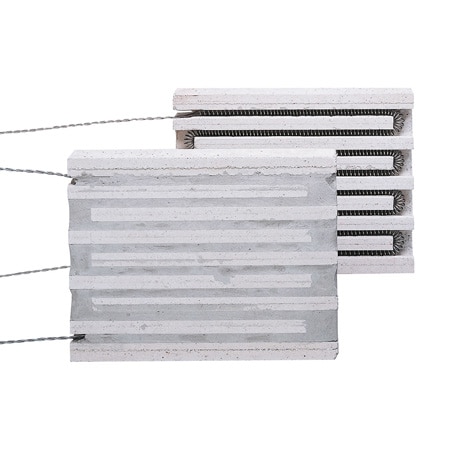

In a ceramic band heater nickel chrome wire is embedded in a flexible outer wall made of special interlocking ceramic tiles which are assembled like a brick wall. Ceramic bands are recommended here because efficient heat transfer is not affected by irregular surfaces or loose fit. They were designed and manufactured as laboratory heaters for use in research and development at e i. Recognizing the many advantages of ceramic insulated heaters many oem customers include them as standard components.

This construction minimizes heat loss and reduces electrical consumption by 20. Ribcage heating mounting configuration.