Glass Ceramic Ltcc

Multilayer ceramics technology htcc and ltcc.

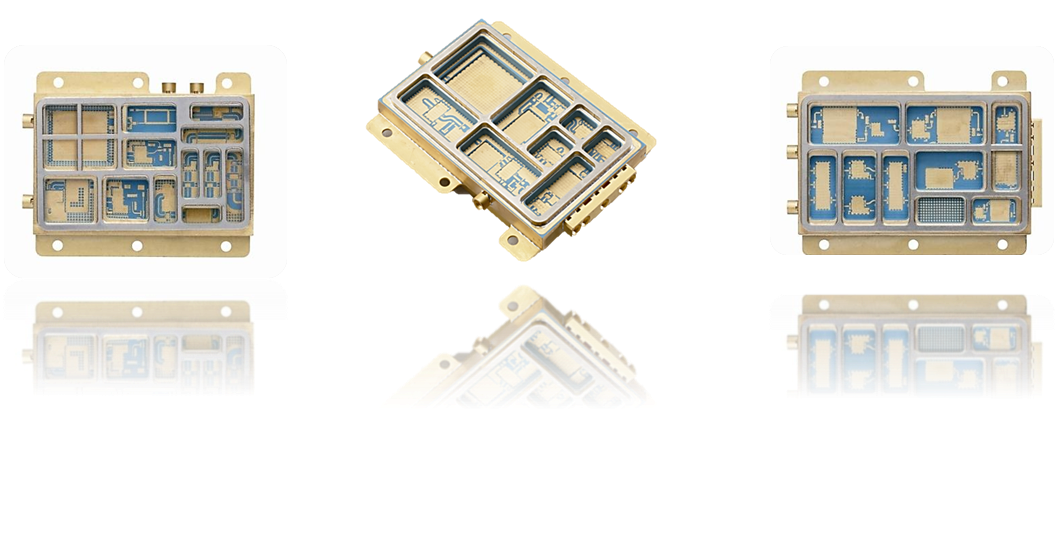

Glass ceramic ltcc. It is sometimes referred to as glass ceramics because its composition consists of glass and aluminum. Click image to view largerlow temperature co fired ceramic ltcc is a multilayer glass ceramic substrate that provides an alternative to the pcb printed circuit board for packaging electronic circuits. Therefore it has the. Science and technology 2002.

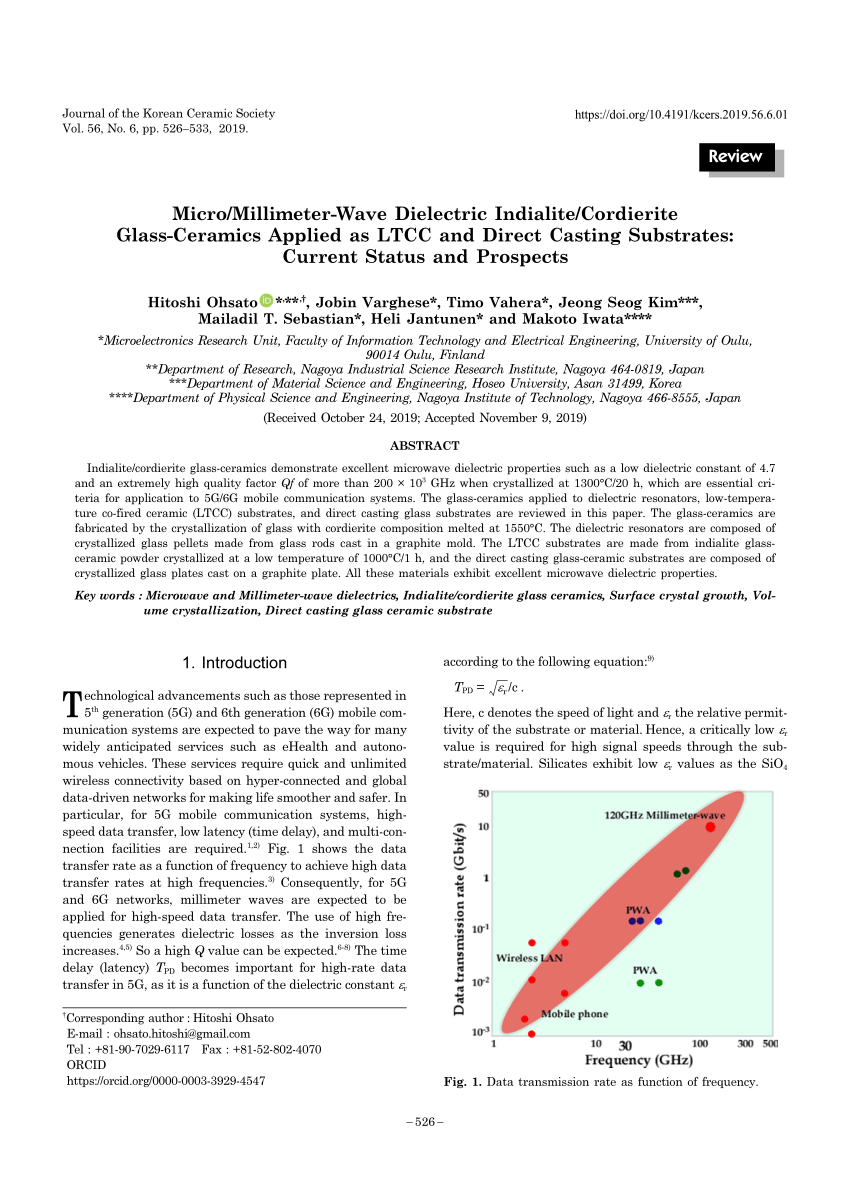

Ltcc low temperature co fire ceramics is a multi layer glass ceramic substrate which is co fired with low resistance metal conductors at low firing temperature less than 1000. 52 9 1 introduction. 2 3 low cost multilayer ceramic package for flip chip mmic up to w band. It is a very interesting thought to employ lb based glass ceramic and labo 3 to develop new low temperature sintering glass ceramic ceramic composite for ltcc application for the attempt to construct composite based on precipitated crystalline phase as ceramic filler and homologous glass ceramic as sintering additive has seldomly been taken.

Value added services ferro takes great pride in our reputation for providing customers with superior technical service and manufacturing support. The ceramics are produced by mixing ceramic and glass powders of specific composition and small quantities of binding agent and solvent to create a homogeneous slurry. Utsumi in encyclopedia of materials. 9 ltcc market and htcc market by end use industry page no.

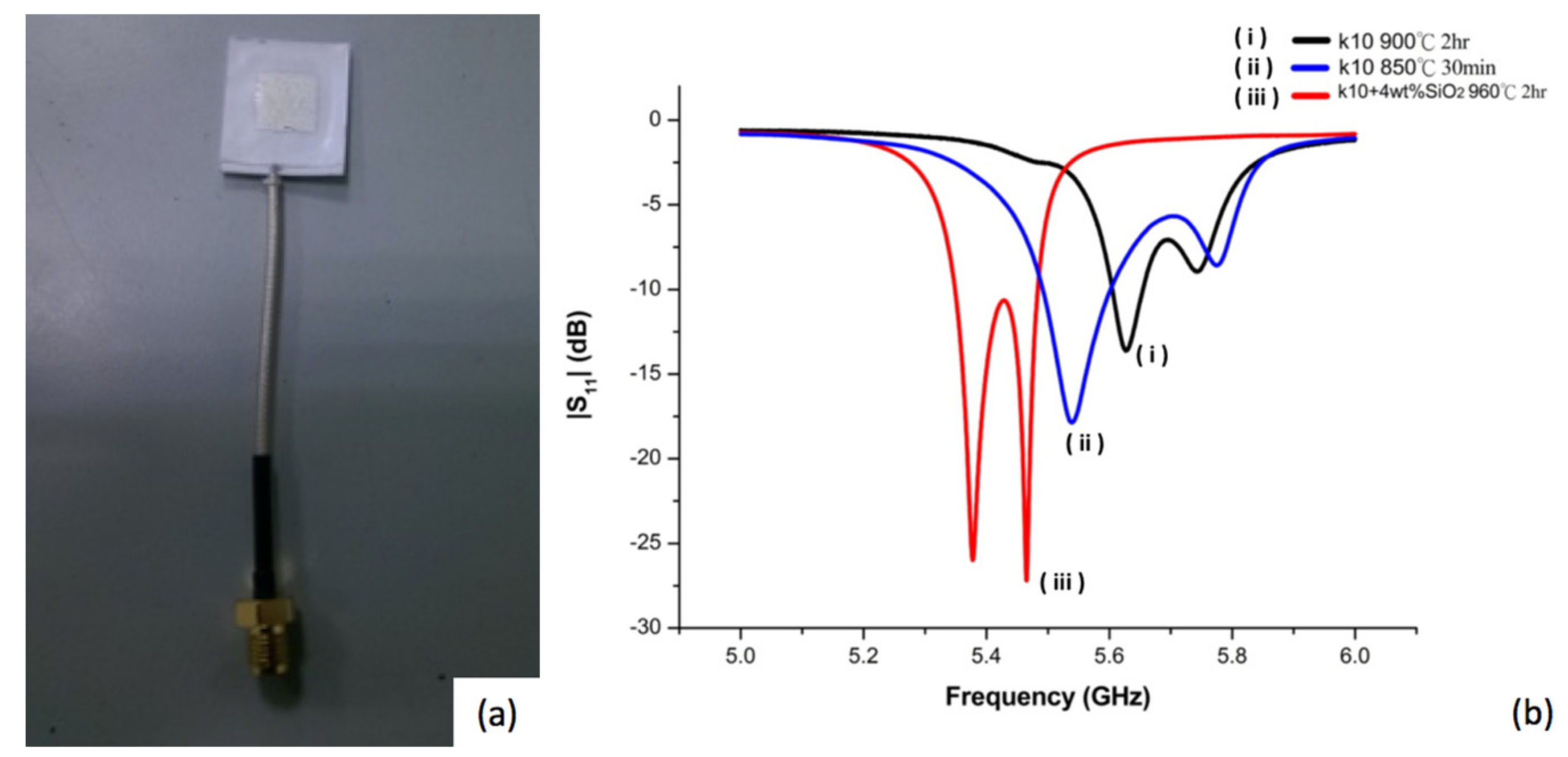

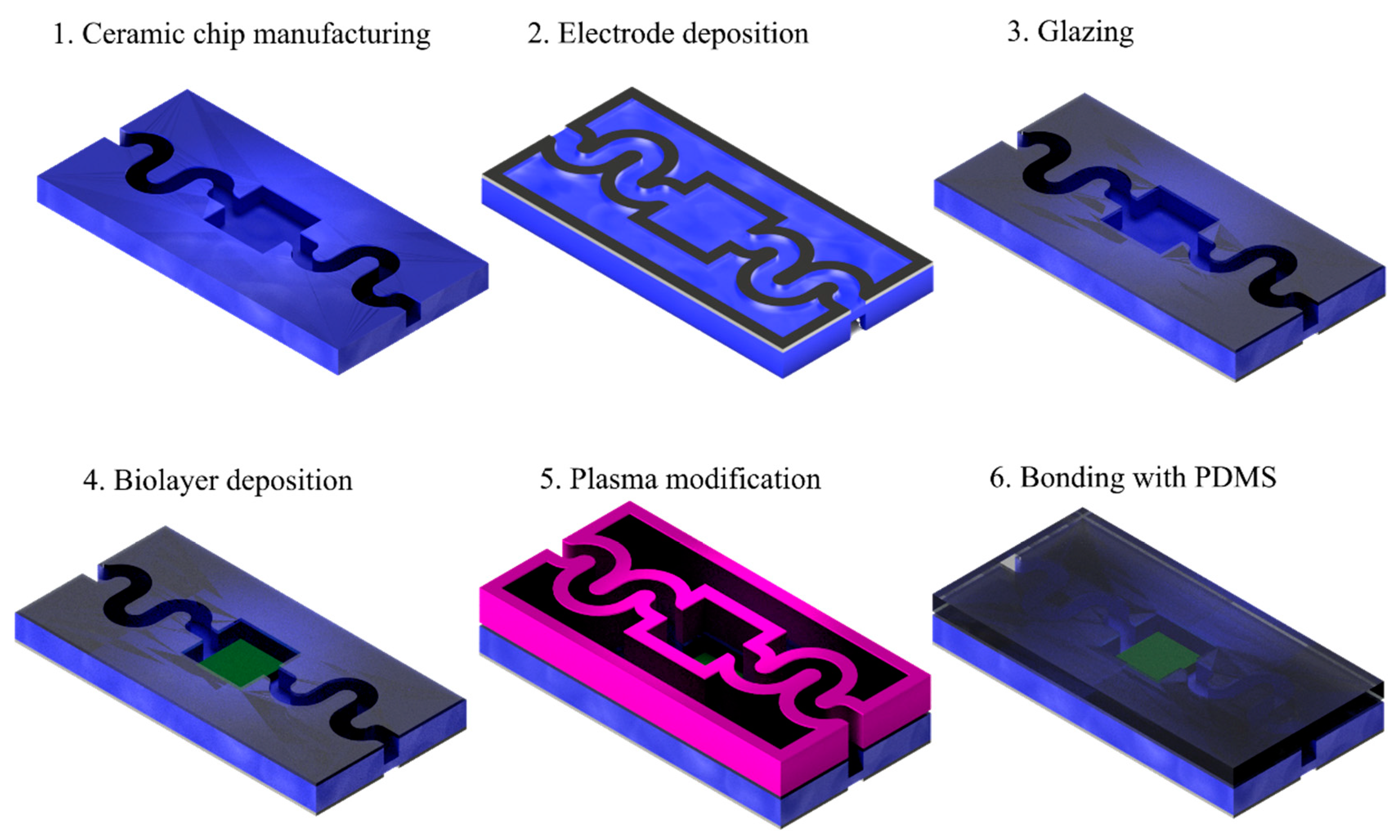

This slurry is then cast to form sheets of uniform thickness about 100 μm 500 μm. Our highly skilled technical professionals combine decades of experience with. The low temperature co fired ceramic ltcc material was developed with the limg 0 9 zn 0 1 po 4 ceramic added cao b 2 o 3 sio 2 crystallizable glass via the traditional solid state reaction process. A low cost multilayer low temperature co fired ceramic ltcc package based on a mass production design rule for an mmic up to w band has been developed.

8 2 glass ceramic material 8 2 1 low cost and high performance of glass ceramic material are driving the market 8 3 ceramic material 8 3 1 high performance in extreme temperature increases the demand for ceramic materials in the ltcc market and htcc market. Ferro ltcc glass ceramic powder formulations product data. The addition of cbs glass can reduce the sintering temperature of limg 0 9 zn 0 1 po 4 ceramic from 950 c to 850 c without an obvious degradation of the microwave dielectric properties as. Therefore it is of great significance to study glass free ltcc microwave dielectric ceramics in which ion substitution is one of such methods.

Ltcc glass ceramic powder formulations product information. This study aimed at developing a high performance low temperature co fired ceramic ltcc green tape with good sintering characteristics and dielectric properties based on a borosilicate glass al 2 o 3 system. First the ca mg ratio in the glass composition was optimized to modify the microstructure sintering density and dielectric properties.