Glass Ceramics With Good Machinability

If the criterion by baik et al.

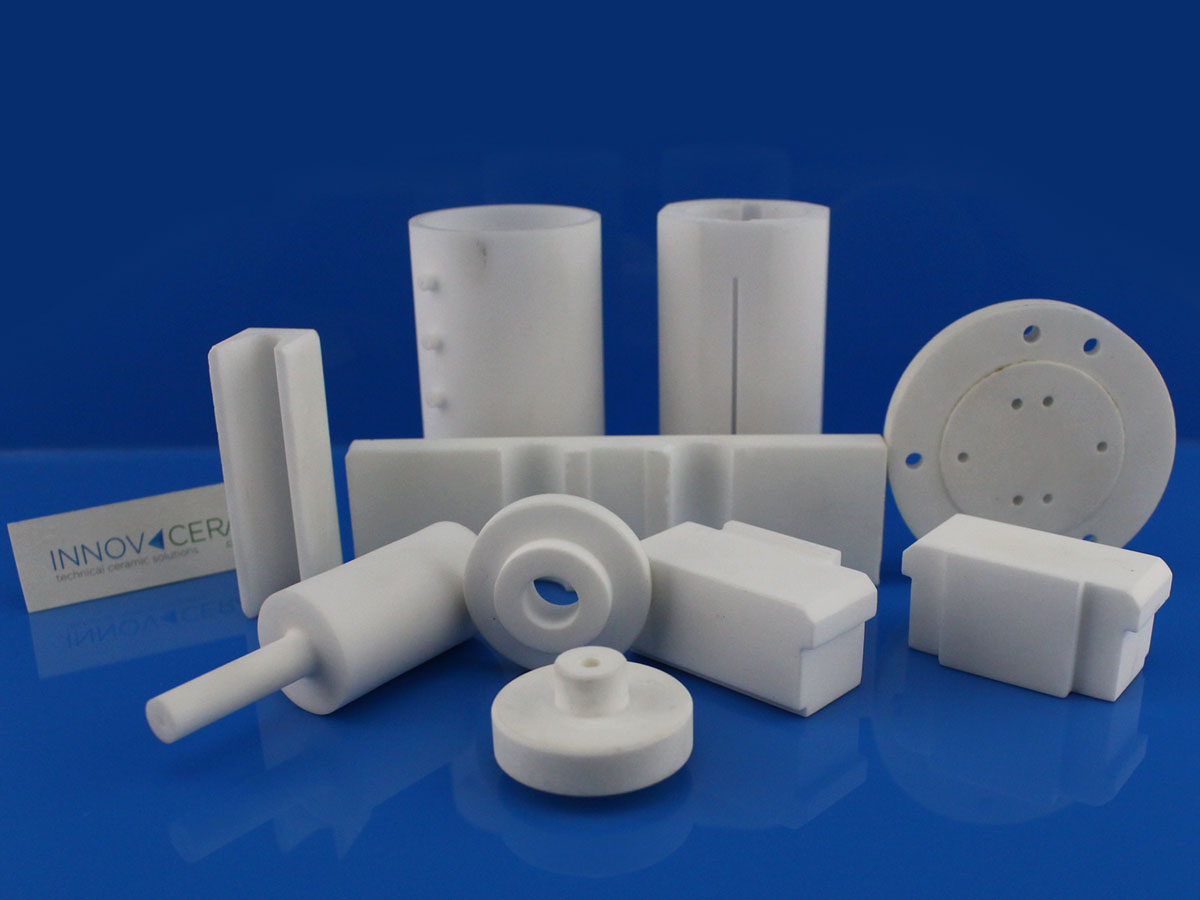

Glass ceramics with good machinability. 3 good machinability occurs when the brittleness index of the material is lower than b zz 4 3 pm 2. It processes good machinability and can be lathed milled planed ground bored incised and threaded. The term machinability covers many operations including turning drilling cutting and threading. The thermal expansion of ceramics isn t as good as that of glass ceramics but for silicon carbide one of the stiffer ceramics its stiffness is a huge advantage.

Macor machinable glass ceramic machining information. Its coefficient of thermal expansion readily matches mos. Globalspec product announcement for machinable glass ceramics have good machinability machinable glass ceramic has a continuous use temperature of 800ºc and a peak temperature of 1000ºc. It is these crystals which stop microscopic fractures at the tool tip from spreading through the material thus making it.

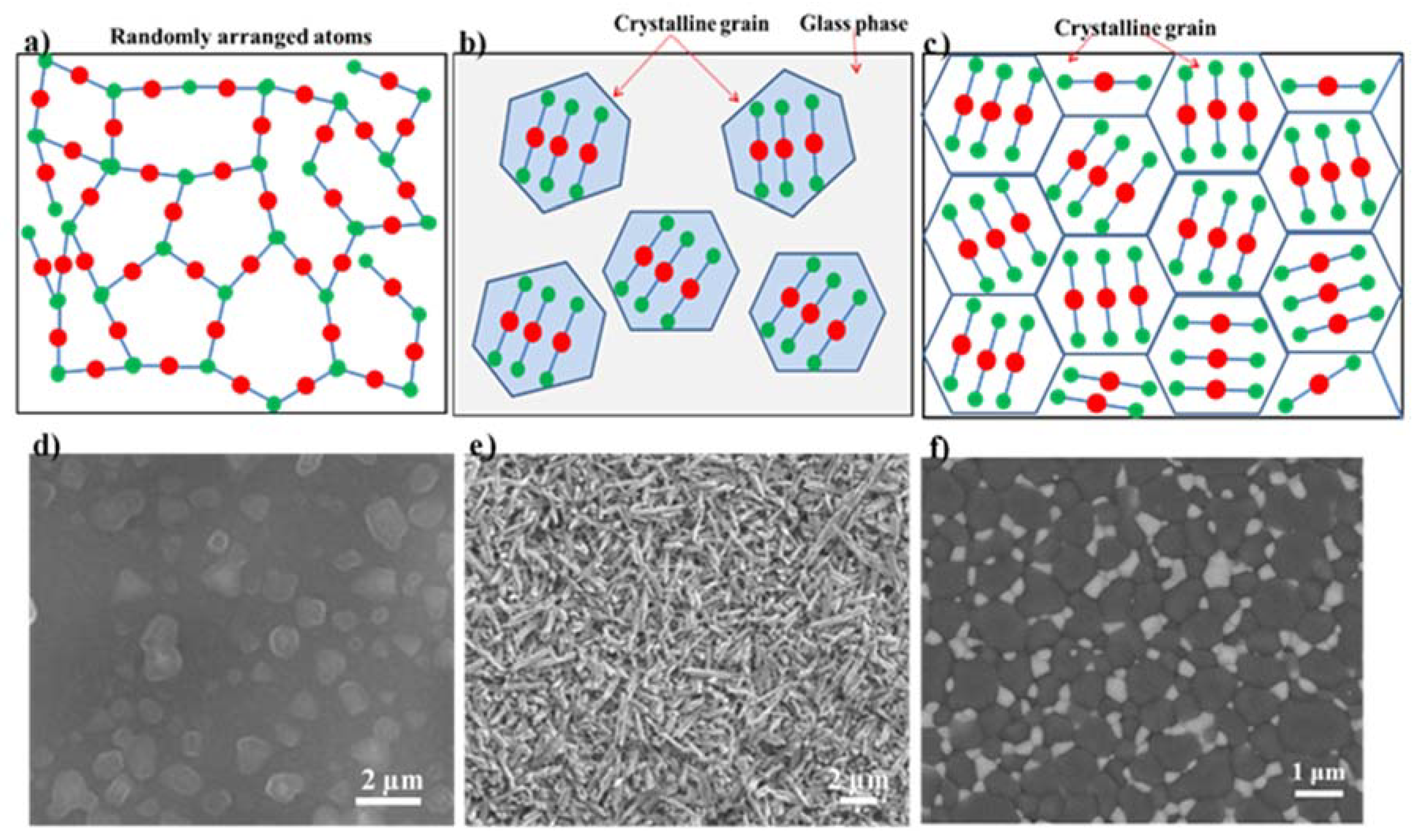

Macor consists of interlocking plate like mica crystals in a glassy matrix. In duplex stainless steels 1997. For lapped and polished parts glass or ceramics can be processed more easily than metals using optical fabrication techniques thereby incorporating optical features such as a. Macor can be machined to make precision components but its machining characteristics are different to metals and plastics.

The lower alloyed duplex grades such as s32304 are comparatively easy to machine 7 and behave in a similar manner to austenitic grades such as 316 or 317 for machining with high speed steel hss tools and with 317ln and 317lmn for. The brittleness index b therefore should be preferred over hardness or toughness in order to predict the machinability of glass ceramics.