Glass Mat Thermoplastic Gmt

Direct long fiber thermoplastic d lft.

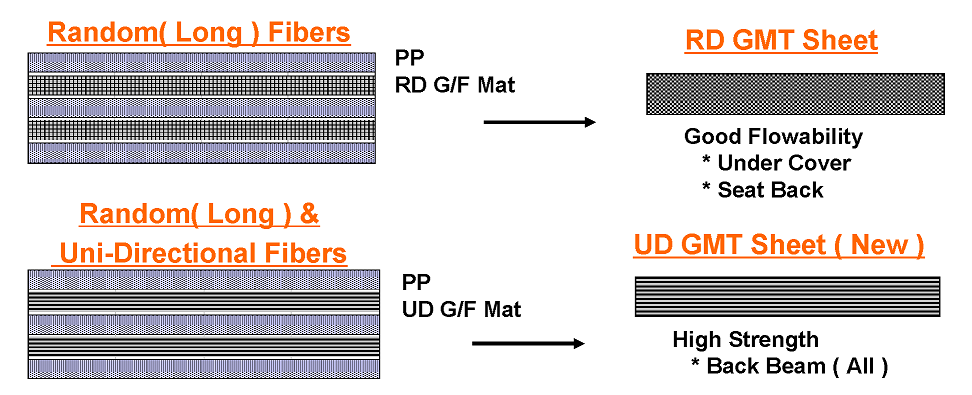

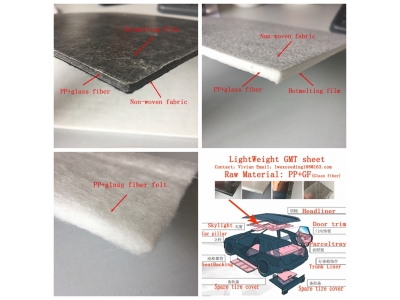

Glass mat thermoplastic gmt. Homogenous material due to consistency of glass content and length. Iht can work with you to develop the required heat cycle time for your particular thermoforming material requirement. Iht glass mat thermoforming ovens can be used for gmt carbon fiber abs smc composites thermoplastics and more. A classic glass mat reinforced thermoplastic gmt and two other configurations of the gmt materials were considered for the desired application.

Glass mat reinforced thermoplastic gmt tre gmt is a thermoplastic pre peg which offers better mechanical properties than injection molded reinforced thermoplastics due to the higher residual length of the glass strands gmt is widely used in automotive applications such as underbody shields seat structures and front ends. Glass mat thermoplastic gmt strong partnerships with key gmt suppliers globally. Typically used for structural parts such as bumpers and underbody shields. Since 2009 stronglite has held 70 of the global market share for gmts.

In 1986 the chevrolet corvette used approximately 40 lb 18 1 kg of azdel s continuous randomly oriented glass mat gmt product in parts ranging from the front bumper beam 10 lb 4 5 kg to the car s two seat shells 13 lb 5 9 kg each and a variety of small parts such as rear floor compartment doors spare tire well console parts and carpet supports another 17. Gm has been named the 2015 hall of fame winner by the automotive division of the society of plastics engineers spe. The classical gmt consists of an endless fiberglass mat that reinforces a polypropylene pp laminate with randomly oriented glass fibers. The first use of glass mat thermoplastic gmt composite on the front bumper of the 1984 model year my chevrolet corvette sports car from then general motors corp.

Stamping is normally restricted to semicrystalline polymers which can be permanently deformed at temperatures between the glass transition t g and melting points and utilises a system similar to that depicted in. Glass fiber mat reinforced thermoplastics mass production of stronglite began in 1995 and it has become highly regarded for its advanced technological properties and quality. Mitsubishi chemical advanced materials is considered the world market leader in the production of classic glass mat reinforced thermoplastics gmt.