Glass Mica Ceramic Machining

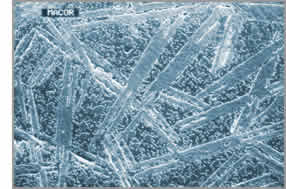

These randomly oriented crystals are key to the machinability of macor.

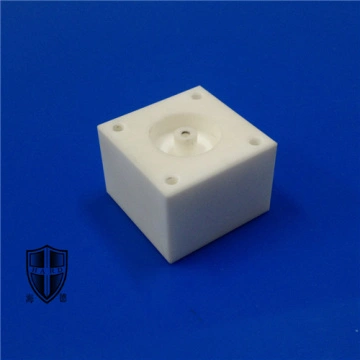

Glass mica ceramic machining. For best results tools must be sharp and checked frequently. With cost containment as a driver the average shop needs only to learn some of the basics to start machining the machinable class of ceramic material like macor alumina silicate boron nitride and other glass mica composites make up the majority of this class. Glass mica ceramic sheets machine complicated shapes and precision parts from these glass mica ceramic sheets in a fraction of the time it would take using other types of fired ceramic. As a premier macor distributor ceramic products can offer assistance in applying this unique material to solve your specific engineering needs.

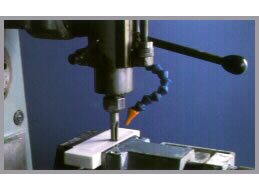

Our capabilities include cnc turning cnc milling cnc drilling and cnc grinding of macor and we have all of the necessary support equipment for producing close tolerance complex parts. Processes which have been honed over the. Machining guidelines of glass mica composite materials standard machine shop equipment can be used in machining glass mica composite materials. Call for assistance 1 800 887 3622 or order stock shapes.

Click to download macor technical specifications pdf. Macor is a mica glass ceramic material with a unique combination of properties. You can machine complicated shapes and precision parts from it in a fraction of the time it would take using other types of fired ceramic. Glass mica ceramic sheets machine complicated shapes and precision parts from these glass mica ceramic sheets in a fraction of the time it would take using other types of fired ceramic.

Its good electrical and thermal resistance make it a common choice for heating and soldering fixtures. Macor is a machinable glass ceramic made by corning incorporated. This video details some of the machining processes used by mtc wesgo duramic in the working of macor glass ceramic. Despite its machinability the material is still abrasive causing some wear of cutting edges.

.jpg)